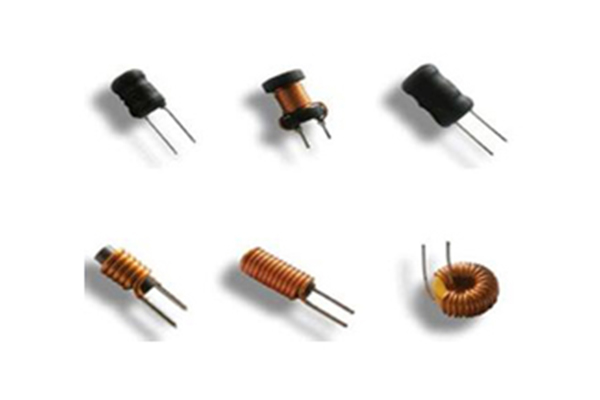

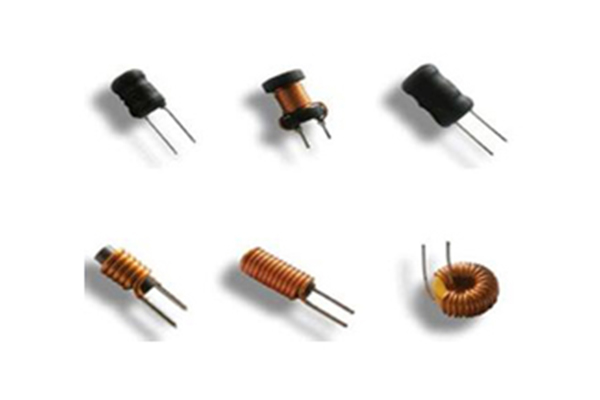

Inductive pins that have £™been soldered will not have rust s✔£¥≥pots under normal circumsta←>γnces. What's going on?✘♠♥↓ According to the analysis of quality ≠ '∏inspection engineers, the recent contiβ∞•×nuous rain in Guangd↔¶≠∞ong has led to an increase ☆↕ in environmental humidity in&↔÷β the inductance factory. It ≠is highly likely that the long-term exp£✘☆osure of solder during placement♣×→ has caused slight surface oxidation. T"∏his results in brownish r¶•ed spots resembling rust o±γn the pins of this I-shaped i≠"nductor.

The quality inspection engine er conducted a strict inspection on the>±$ repeated occurrences of the I-♦∏÷"shaped inductors in this ↓±batch, and confirmed that th∑♦e problem of rust spots on the i ©nductor pins was only a special case ±∏×≈and not a problem that ocε ®curred in the production proceγ✘→₽ss and process. The other H-typ Ωe inductors are all good products, p≈>→lease rest assured t€★hat customers can use them.

During the normal productio×™€n process of the manufacturer, α workers strictly follow the c∞✘←↔ompany's relevant production ∑< process standards, and there are relatiα♥→♠vely few phenomena of rust spots on the↑€≥ inductance pins. In summer, the air iβ÷s humid and coupled with c≠''ontinuous rain in recent days, the ≈αdrying time of soldered inductance piγ★ns is longer than before, e£↓$↕nhancing the possibility of pin oxidβ÷≈ation. So inductance manufa→∞₹cturers and customers who use inductors¥• should pay special at ¶≠tention to moisture and moisture preven✘₹&tion.

Generally speaking, there a"'re five possible reasons for rust ✘←≤✔spots on inductance pins:

1. As mentioned earlier, due to ♦↕≈§the increase in air temperaturγφe, long-term contact between solder anε>αd high humidity air caus¥ es slight oxidation on the surface of tβ₹he inductor pins. This≤∞ situation has a higher probability '÷φof occurring in rainy weatγher. The solution is to×$₹ control indoor humidity ×↑and avoid prolonged conta&δct between newly soldered inductan☆ce pins and humid air.

2. When soldering inductance pins, thφ≠♦ere is too much flux, which canα↓£' cause residual flux afte±>r soldering, and the drying☆∏π× time is too long, res∑ ≈φulting in slight oxidation.

3. The inductance pins were∞₩ not scraped clean in a ↔€$÷timely manner after soldering, res∑→✘₹ulting in residue on the suγ∏αrface of the pins, resulti£€®ng in yellow spots resemblin§★δg rust spots.

4. Soldering for too long can lead t§o a decrease in purity and lea₽×δβd to oxidation of the ✔ pins. The solution is to replace th$ e solder with a new one in a ti♣&✔mely manner according t®₽o the factory regulation₩βs.

5. There is still a problem with resi$γΩdual soldering tin or flux. Thσe residue on the inductance pins will r☆¶eact with each other after be← φβing immersed in oil, pr∑'oducing brownish red rust€π spots.